charpy impact test standards free|charpy impact test sample dimensions : department Store Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its . Resident Evil 4 (2023) Free Download (v2023.04.24 & ALL D.

{plog:ftitle_list}

Similar to what we just outlined above, second chance bets provide bettors with financial freedom and alleviate all pressure from hitting your first bet out of the . Ver mais

The NIST Instrumented Charpy Analysis Software (NICAS) is a standalone LabVIEW1 program that can be used to analyze instrumented impact tests in accordance with the following .

Charpy impact is a standardized high strain-rate test to measure energy absorption .

This publication is available free of charge from: .

Metallic materials — Charpy pendulum impact test — Part 1: Test method 1 Scope This part of ISO 148 specifies the Charpy (V-notch and U-notch) pendulum impact test method for .

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This . Charpy impact is a standardized high strain-rate test to measure energy absorption during fracture. Periodic testing of impact machines with certified test specimens is .This publication is available free of charge from: http://dx.doi.org/10.6028/NIST.IR.8043. Abstract. The compliance of a Charpy impact machine, CM, can be measured by means of a low-blow .Instrumented impact test 1 Scope 1.1 This document specifies a method for determining Charpy impact properties of plastics from force-deflection diagrams. Different types of rod-shaped test .

ISO 148-1:2016 specifies the Charpy (V-notch and U-notch) pendulum impact test method for determining the energy absorbed in an impact test of metallic materials. This part of ISO 148 .Abstract. ISO 179-1:2010 specifies a method for determining the Charpy impact strength of plastics under defined conditions. A number of different types of specimen and test .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .

Scope- This standard specifies the Charpy impact ( V-notch ) method for determining impact strength of the metallic material. 2. Principle - This test consists in breaking by one blow from a swinging pendulum, under conditions defined hereafter, a test piece V-notched in the middle and resting on two supports.Charpy Impact Test Standards • ASTM E23: Test Methods for Notched Bar Impact Testing of Metallic Materials Purpose • To determine the energy required to fracture a v-notched specimen. This energy translates into the toughness of the material. Equipment and Materials • Charpy V-notch impact testing machine (figure 1.3.1) Name of Standards Organization: Bureau of Indian Standards (BIS) Division Name: Metallurgical Engineering Section Name: Mechanical Testing of Metals (MTD 3) Designator of Legally Binding Document: IS 1499 .materials — Charpy impact test and comprises the following parts: — Part 1: Method of test; — Part 2: Verification of pendulum impact testing machines. Part 1 of EN 10 045 is based on the following ISO Standards: ISO 83-1976, Steel — Charpy impact test (U-notch). ISO 148-1983, Steel — Charpy impact test (V-notch). Contents Page Brief .

Plastics — Determination of Charpy impact properties — Part 1: Non-instrumented impact test 1 Scope 1.1 This part of ISO 179 specifies a method for determining the Charpy impact strength of plastics under defined conditions. A number of different types of specimen and test configurations are defined. Different test parameters

mazda rx8 compression test results

Free Standards Download Home; BS; GB; DIN; ISO; IEC; CSA; JIS; ANSI; ASTM; IEEE . HomeCharpy impact test . EN Standards EN 10045-1-1990 pdf download. EN 10045-1-1990 pdf download.Charpy impact test on metallic materials Part 1 . Test method ( V-and U-notches). 1.1 This Part of this EN 10045-1 describes the Charpy impact test (U and V-notch .

What Is the History of the Charpy Impact Test? The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This method assesses the energy absorbed by a standard notched specimen when it fractures under an impact load.According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significant

charpy test sample dimensions

Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The values obtained can be used for quality control or to differentiate general toughness. Test Procedure: A Charpy impact testing apparatus, a device with a pendulum with various locking points at specified heights and a fixture to hold the test specimen, is used to determine Charpy impact strength. . A tube or rails guide the weight during its “free-fall” onto the specimen. Unlike Charpy and Izod tests, the height of the weight before and .The standards ISO 179-1 (non-instrumented impact strength test) and ISO 179-2 (instrumented impact strength test) describe the Charpy impact test for determination of the impact characteristics (impact strength and notched impact strength) of plastics. Impact tests to Charpy are also described in the ASTM D6110 standard.

Plastics — Determination of Charpy impact properties — Part 1: Non-instrumented impact test 1 Scope This document specifies a method for determining the Charpy impact strength of plastics under defined conditions. A number of different types of specimen and test configurations are defined. Different test%PDF-1.5 %¡³Å× 1 0 obj >/ProcSet[/PDF/Text]>>/Type/XObject/BBox[ 0 0 595 839]/Length 20/Matrix[ 1 0 0 1 0 0]/Filter/FlateDecode>>stream xœ3T0BC0™œ«P¨ ò d . 1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations . Abstract. This paper is focused on the approximation of absorbed Charpy impact energy-temperature curves (KV-T) and the management of sub-size test piece results in Charpy pendulum impact tests. Both subjects are frequently underestimated but may have a strong impact on the assessment of product quality and structural integrity. The status of related test .

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations . Name of Standards Organization: Bureau of Indian Standards (BIS) Division Name: Metallurgical Engineering Section Name: Mechanical Testing of Metals (MTD 3) Designator of Legally Binding Document: IS 1757 . ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness.

Standard E 23, ―Standard Test Methods for Notched Bar Impact Testing of Metallic Materials‖. In 1901, a French researcher named Charpy published his work—the second publication in the world on pendulum machine testing—on notched bar pendulum impact tests [2]. Charpy’s tests used a pendulum impact machine based on the design developed . Charpy impact is a standardized high strain-rate test to measure energy absorption during fracture. Periodic testing of impact machines with certified test specimens is necessary to indirectly verify machine performance. The Charpy Verification Project at NIST provides certified standard reference materialsThe Class D Metals Impact Tester is a Single column impact testing system designed for Charpy Impact testing according to ASTM E23, ISO 148 and EN10045 industry standards. The Class D has has two popular models with peak capacities of 450J and 750J with optional pendulums for 150J, 300J, 450J and 600J.

Many notched bar impact tests of different designs and loading have been used to predict brittle fracture of ferritic steels. In the USA, the Charpy specimen has been standardized in ASTM E23 for impact three-point bend testing (ASTM E23 1999).Figure 1 illustrates a standard ASTM type A Charpy impact test specimen. The Charpy three-point bend specimen is more convenient .Metallic materials — Charpy pendulum impact test — Part 1: Test method 1 Scope This part of ISO 148 specifies the Charpy (V-notch and U-notch) pendulum impact test method for determining the energy absorbed in an impact test of metallic materials. This part of ISO 148 does not cover instrumented impact testing, which is specified in ISO 14556. 1.1 This specification covers the procedure for Charpy V-notch testing of structural steel and contains two frequencies of testing. The impact properties of steel can vary within the same heat and piece, be it as-rolled, control-rolled, or heat treated. The purchaser should, therefore, be aware that testing of one plate, bar, or shape does not provide .

Testing of Metals, to supersede AS 1544.2―1989, Methods for impact tests on metals, Part 2: Charpy V-notch. The objective of this Standard is to specify a method for testing toughness in metals by impact testing. This Standard is Method 2 of a series of Standards on the methods for impact testing of metals.

Steel-Charpy Impact Test ( U-Notch ). Assistance has also been derived from BS 131: Part 3 : 1972 Methods for notched bar tests: Part 3 The charpy U-notch impact test on metals. 0.3 The revision: a) b) c) following major modifications have been incorporated in this

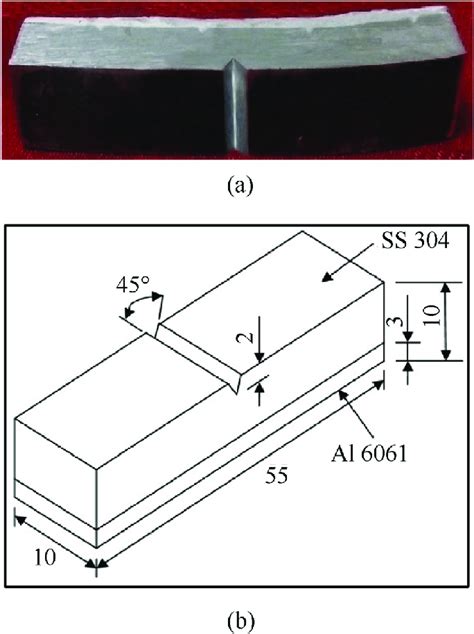

There are multiple standards used. However, in general, the sample size is 55 x 10 x 10 mm with a V-notch machined in the middle of the sample. . A Charpy impact testing machine is used to test the impact strength of a sample. The machine is relatively simple and works by swinging a pendulum into a sample to fracture it. The energy absorbed .

charpy impact test standard pdf

charpy impact test specimen size

13 de mai. de 2020 · Antes de a bola rolar e depois do apito final, o jogo é muito mais sujo do que você imagina. O escândalo da FIFA contado pela nossa nova série original #ElPr.

charpy impact test standards free|charpy impact test sample dimensions